What is Ball Valve?

A ball valve is a type of quarter-turn rotational motion valve that uses a ball-shaped disc to control the flow of fluid. The valve is designed to be either fully open or fully closed, providing a quick and efficient means of starting or stopping the flow. The key components of a ball valve include the ball (disc), a stem that connects to the actuator, and a handle or actuator for manual or automated operation.

Ball valves are essentially offered in three variations: full port, venturi port, and reduced port. The full-port valve features an internal diameter identical to the inner diameter of the pipe. In contrast, venturi and reduced-port versions typically have an internal diameter one pipe size smaller than the line size.

Types of Ball Valves

Ball valves are manufactured in various body configurations, and the most common types include:

Product Data

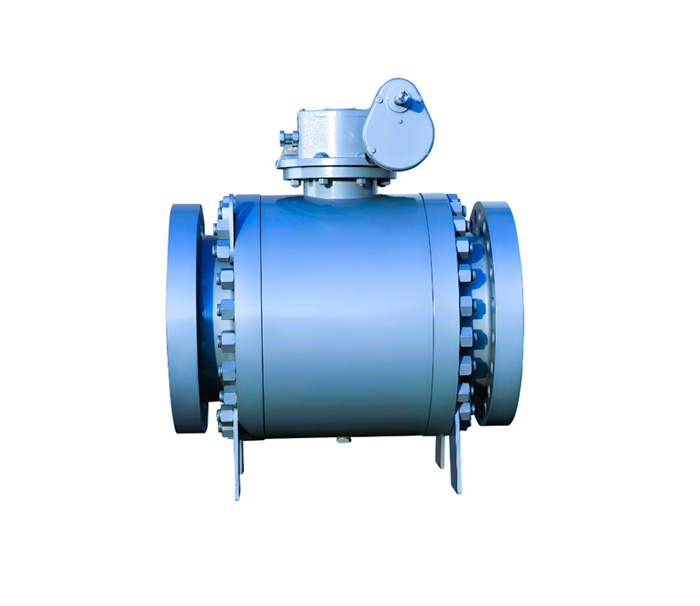

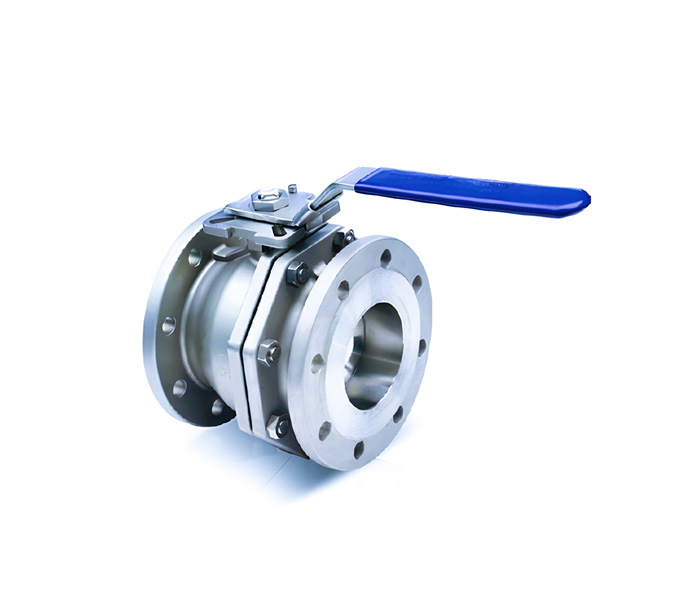

Arrotop Ball Valves are designed for precise control and shutoff of fluid flow. These valves are essential for applications requiring quick operation and reliable sealing, suitable for water treatment, oil and gas, chemical processing, and more.

Arrotop Ball Valves offer high performance, reliability, and versatility for various industrial applications. With a focus on quality and innovation, Arrotop provides products that ensure superior performance and longevity. For more details or to place an order, contact our sales team.

Key Features

- Design: Quarter-turn valve with a ball-shaped disc.

- Operation: Available in manual, gear, or actuator-operated configurations.

- Applications: Water, oil, gas, chemical processing, and more.

- Durability: High-quality materials for long-lasting performance.

- Sealing: Excellent sealing capabilities for leak prevention.

- Standards: API 608, ASME B16.34 compliance.

- Anti-Corrosion Coating: Available with anti-corrosion coatings for enhanced durability in harsh environments.

- Maintenance: Designed for easy maintenance with replaceable parts. Engineered to provide high flow capacity with minimal pressure drop.

- Leak-Proof Design: Ensures leak-proof operation under high pressure.

- Special Applications: Steam, thermal, fire, chlorine, all-welded, low temperature, rapid-cycle service.

Technical Specifications

- Sizes: From 1/8″ to 12″ (DN 6 to DN 300)

- Pressure Ratings: Class 150 to Class 2500, up to 6000 psi (414 bar)

- Materials: Stainless steel (SS304, SS316), carbon steel, brass, and special alloys

- Temperature Range: -50°C to 650°C

- End Connections: Flanged, threaded, socket weld, butt weld, tube weld

- Design Features: Full bore, reduced bore, anti-static, fire-safe design, bi-directional flow

- Seat Materials: Reinforced PTFE, PEEK, UHMWPE, Virgin PTFE, Alloy X-750

Construction Details

- Body and Bonnet: Cast or forged construction with bolted bonnet

- Ball: Precision-machined for smooth operation

- Seats: Available in soft or metal-seated designs

- Stem: Blow-out proof design for safety

- Gland: Adjustable for enhanced sealing

- Packing: High-quality packing to prevent leakage

Model Numbers and Sizes

| Model Number | Size (in) |

|---|---|

| AR-BV-150-01 | 1/8″ |

| AR-BV-150-02 | 1/4″ |

| AR-BV-300-03 | 1/2″ |

| AR-BV-600-04 | 1″ |

| AR-BV-900-05 | 2″ |

| AR-BV-1500-06 | 3″ |

| AR-BV-2500-07 | 4″ |

| AR-BV-150-08 | 6″ |

| AR-BV-300-09 | 8″ |

| AR-BV-600-10 | 10″ |

| AR-BV-900-11 | 12″ |

Technical Information :

- Fire Safety: Certified as per BS 6755 Part 2, API 6FA, API 607, and ISO 10497.

- Pressure Testing: Conducted according to API 598, ISO 5208, and API 6D standards.

- Floating and Trunnion Ball Design: Ensures optimal performance for various applications.

- Split Body Design: Available in 2-piece and 3-piece configurations.

- Face-to-Face Dimensions: Conform to ANSI B16.10 and API 6D.

- End Connections:

– Flanged RF, RTJ (ANSI B16.5)

– Socket Weld (ANSI B16.11)

– Butt Weld (ANSI B16.25)

– NPT (ANSI B1.20.1)

– BSPP (BS 21, ISO 228/1, DIN 259)

– BSPT (BS 21, ISO 7/1) - Anti-Blowout Stem: Ensures safety and reliability.

- Antistatic Stem: Provides additional safety.

- Self-Adjustable Packing: Maintenance-free design.

- Cavity Pressure Relief: Built-in feature to prevent pressure build-up.

How a ball valve works

- Open Position: When the valve is open, the ball rotates to a position where the bore (hole) through the ball is in line with the inlet and outlet ports of the valve body. This creates an unobstructed pathway for fluid flow, allowing it to pass through the valve.

- Closed Position: When the valve is closed, the ball is rotated to a position where the bore is perpendicular to the flow openings of the valve body. This blocks the flow path, preventing the fluid from passing through, and effectively shuts off the valve.

Dimensional Data (Face-to-Face Dimensions in mm)

| Size (in) | Class 150 | Class 300 | Class 600 | Class 900 | Class 1500 |

|---|---|---|---|---|---|

| 1/2″ | 140 | 140 | 165 | 216 | 216 |

| 3/4″ | 152 | 152 | 190 | 229 | 229 |

| 1″ | 165 | 165 | 216 | 241 | 241 |

| 1.5″ | 191 | 191 | 241 | 292 | 292 |

| 2″ | 216 | 216 | 292 | 368 | 368 |

| 2.5″ | 241 | 241 | 330 | 381 | 381 |

| 3″ | 283 | 283 | 356 | 457 | 457 |

| 4″ | 305 | 305 | 432 | 610 | 610 |

| 6″ | 403 | 403 | 559 | 737 | 737 |

| 8″ | 502 | 502 | 660 | 838 | 838 |

| 10″ | 568 | 568 | 787 | 965 | 965 |

| 12″ | 648 | 648 | 838 | 965 | 965 |

Applications of Ball Valves

- Water Treatment Plants: Reliable performance in controlling water flow.

- Oil Refineries: Suitable for handling crude oil and other petroleum products.

- Gas Processing Facilities: Effective in managing the flow of natural and industrial gases.

- Chemical Plants: Resistant to corrosive chemicals and high temperatures.

- Power Plants: Used in various systems for efficient flow control.

- Quick and Easy Operation: Ball valves have a simple design that allows for quick and easy operation. The 90-degree turn of the lever or handle from fully open to fully closed positions makes them convenient for both manual and automated control systems.

- Low Maintenance: Due to their simple design and fewer moving parts compared to other types of valves, ball valves generally require less maintenance. This can result in cost savings and increased efficiency over time.

- Versatility: Ball valves are versatile and can be used in a wide range of applications, including water and wastewater systems, oil and gas, chemical processing, and more. They are available in various materials, such as stainless steel, brass, and PVC, making them suitable for different environments.

- Bubble-Tight Sealing: Ball valves provide excellent sealing properties, ensuring a tight shut-off and preventing leakage. This is crucial in applications where precise control of the flow or complete isolation of the fluid is necessary.

- High Pressure and Temperature Resistance: Ball valves are capable of handling high-pressure and high-temperature applications, making them suitable for challenging industrial environments. The materials used in the construction of ball valves are often selected based on the specific requirements of the application.

- Rapid Opening and Closing: The quarter-turn operation of ball valves allows for rapid opening and closing, making them ideal for applications where quick response times are essential, such as emergency shutdown systems.

- Bi-Directional Flow: Ball valves are designed to allow for bidirectional flow, meaning they can effectively control the flow of fluids in both directions. This flexibility enhances their usability in various systems.

- Compact Design: Ball valves typically have a more compact design compared to other types of valves, making them suitable for applications where space is limited.

- Cost-Effective: Due to their simplicity and ease of manufacturing, ball valves are often more cost-effective than other types of valves. This makes them an economical choice for a wide range of applications.

- Reduced Fluid Resistance: The full-bore design of some ball valves minimizes fluid resistance, allowing for better flow characteristics and efficiency in certain applications.

Advantages of Ball Valves

- Quick Operation: Ball valves can be quickly opened or closed with a 90-degree rotation of the handle or actuator. This allows for rapid on/off control, making them suitable for applications where quick response is essential.

- Full Flow Capacity: In the fully open position, ball valves provide an unobstructed and full-flow pathway for fluids. This design minimizes pressure drop and allows for maximum flow capacity.

- Tight Shutoff: Ball valves provide a tight seal when in the closed position, preventing the passage of fluids. This feature is crucial in applications where leakage or seepage is not acceptable.

- Versatility: Ball valves are versatile and can handle a wide range of fluids, including liquids and gases. They are used in various industries, such as oil and gas, water treatment, chemical processing, and more.

- Simple Design: Ball valves have a relatively simple design with few moving parts. This simplicity makes them easy to operate, maintain, and repair, contributing to their overall reliability.

- Bidirectional Flow: Ball valves typically allow bidirectional flow, meaning they can control the flow of fluid in both directions. This enhances their flexibility in various piping systems.

- Low Maintenance: The simple design of ball valves often translates to low maintenance requirements. Their components are easily accessible, facilitating inspections and repairs.

- Durability: Ball valves are generally durable and can withstand a range of operating conditions, including high pressures and temperatures. This durability contributes to their long service life.

- Automation Compatibility: Ball valves can be easily automated using actuators, making them suitable for applications where remote or automatic control is necessary.

- Economical: Ball valves are often cost-effective compared to some other types of valves. Their simplicity, coupled with effective performance, makes them an economical choice for various applications.