What is Valve Manifold?

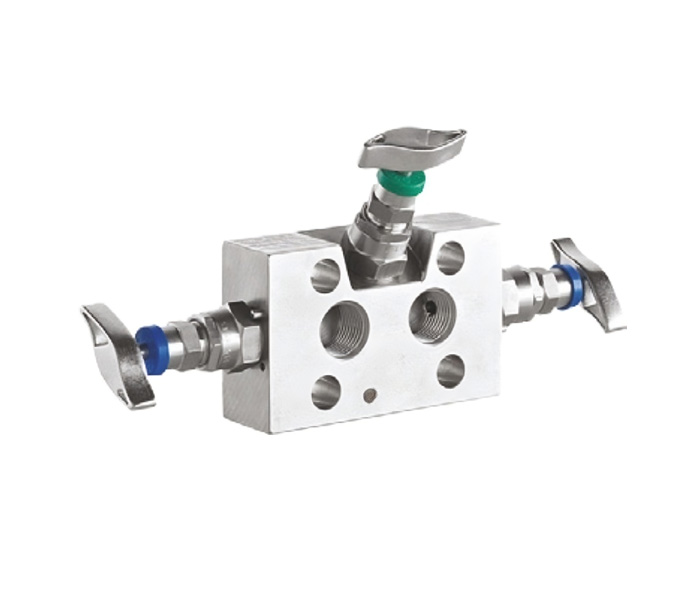

A valve manifold is a component used in fluid control systems, particularly in industrial settings such as oil and gas, petrochemical, and process industries. It is a system that typically consists of multiple valves assembled into a single unit or block. The manifold facilitates the control, regulation, and distribution of fluid flow in a more organized and efficient manner.

Types of Manifold Valves

Product Data

Arrotop offers a comprehensive range of valve manifolds designed for precise and reliable flow measurement and control in various industrial applications. Our valve manifolds are built to meet international standards and provide long-term performance.

A valve manifold is a hydraulic system component, comprising one or more block or isolation valves. A manifold valve plays a crucial role as a fundamental element in pressure and differential pressure transducer systems. The primary function of a manifold valve is to obstruct or separate fluid flow, ensuring the isolation of process media from pressure instrumentation. Integrating a valve manifold into a tool facilitates replacement or calibration without requiring a shutdown.

Typical valves composing a valve manifold include ball, needle, bleed, and vent valves. A manifold valve configured as a block and bleed system prevents the upstream fluid from contacting downstream components by segregating the fluid flow within the system.

Material : Manufactured from forged Stainless Steel – ASTM A 479, ASTM A182 F304, ASTM A182 F316, ASTM A182 F304, ASTM A182 F304L, Carbon Steel – ASTM A 105, Monel, Inconel, Hastelloy, Titanium, and other materials available upon request. NACE-compliant materials are also available.

Features :

- An anti-rotational thrust brush is employed to ensure pressure-tight sealing, maintain consistent packing compression, and minimize the creation of cold flow channels.

- A bonnet/body washer with on-site bonnet retrofitting, ensuring a 100% re-sealing guarantee.

- A T-bar is incorporated for ease of operation.

- Dual cap

- A lock nut for gland adjustment.

- Adjustment of the gland packing to compensate for wear in the gland.

- An anti-blowout spindle, featuring high-quality micro mirror stem finishing, is employed to ensure positive gland sealing.

- The gland packing is designed with minimal air adjustment to achieve optimal sealing.

- The spindle tip provides a bubble-tight shutoff, ensuring a leakage-free performance and downstream functional safety for the user.

Applications of Valve Manifold :

- Process Control Industries: Valve manifolds are extensively used in industries such as chemical processing, pharmaceuticals, food and beverage, and water treatment. They play a vital role in controlling the flow of liquids and gases to ensure precise and efficient processing.

- Oil and Gas Production: In the oil and gas industry, valve manifolds are employed in wellhead control systems, providing a centralized point for managing fluid flow, pressure, and temperature. They are crucial for safety and operational efficiency in extraction, production, and transportation processes.

- Petrochemical Plants: Valve manifolds are integral to petrochemical plants, where they help regulate the flow of various chemicals and gases. Their compact design and versatility make them suitable for complex and diverse fluid control requirements.

- Power Generation: Valve manifolds are used in power plants for controlling the flow of steam, water, and other fluids in boilers, turbines, and auxiliary systems. They contribute to the safe and efficient operation of power generation facilities.

- Instrumentation and Calibration: Valve manifolds are commonly employed in conjunction with pressure transmitters, flow meters, and other instrumentation devices. They provide a centralized point for calibration, testing, and isolation of instruments without disrupting the entire system.

- HVAC Systems: In heating, ventilation, and air conditioning (HVAC) systems, valve manifolds help control the flow of refrigerants and other fluids. They contribute to the efficiency and performance of HVAC systems in commercial and industrial buildings.

- Water and Wastewater Treatment: Valve manifolds play a role in water treatment plants, helping manage the flow of water, chemicals, and additives in treatment processes. They contribute to the optimization of water and wastewater treatment systems.

- Automated Process Control: Valve manifolds are compatible with automated control systems, making them suitable for integration into processes that require high precision, repeatability, and responsiveness.

- Laboratory and Analytical Equipment: In laboratories and analytical settings, valve manifolds are used in gas chromatography, liquid chromatography, and other analytical instruments. They facilitate the controlled flow of gases and liquids for accurate analyses.

- Aerospace Industry: Valve manifolds are utilized in aerospace applications for controlling fluids in aircraft hydraulic systems, fuel systems, and other critical components.

Advantages of Valve Manifold :

- Compact Design: Valve manifolds integrate multiple valves into a single block or panel, reducing the need for extensive piping and creating a more compact and space-efficient fluid control solution.

- Simplified Installation: The manifold design simplifies the installation process, as multiple valves are pre-assembled into a single unit. This can save time and reduce the complexity of piping systems.

- Easy Maintenance: Valve manifolds facilitate easier maintenance and troubleshooting by providing centralized access to valves. This allows for quick isolation, replacement, or calibration of individual valves without disrupting the entire system.

- Improved System Organization: The organized layout of valve manifolds helps streamline fluid control systems. This can lead to better visibility, accessibility, and overall management of the system.

- Reduced Leak Points: The compact design of valve manifolds minimizes the number of potential leak points in a system compared to traditional piping arrangements. This can enhance overall system integrity and reduce the risk of fluid leakage.

- Enhanced Safety: Valve manifolds contribute to improved safety by providing a centralized point for fluid control. This can simplify emergency shutdown procedures and facilitate quick response to potential issues.

- Versatility: Valve manifolds are versatile and can be customized to meet specific application requirements. Different types of valves, materials, and configurations can be incorporated based on the needs of the fluid control system.

- Cost Savings: While the upfront cost of a valve manifold may be higher than individual valves and piping, the overall cost of installation, maintenance, and operation can be lower due to the system’s efficiency and ease of management.

- Automation Compatibility: Valve manifolds are often compatible with automation and control systems, allowing for integration into larger automated processes for enhanced precision and efficiency.

- Pressure Regulation: Manifold valves often include features for pressure regulation, providing better control over fluid pressure within a system.