• ARO-VT-C-001 • ARO-VT-C-002

• ARO-VN-003 • ARO-VC-004

What is Venturi Tube?

A Venturi tube is a device used to measure the flow rate of a fluid, usually a liquid, through a pipeline. The basic structure of a Venturi tube consists of a constricted throat section positioned between two larger diameter sections. The tube’s design creates a pressure difference between the inlet and throat regions, allowing for flow rate measurement.Venturi tubes provide several advantages, including remarkably low pressure loss, heightened durability, and a reduced likelihood of capturing sludge media and sediment compared to alternative throttle elements.

Product Data

Arrotop is a leading provider of precision-engineered flow measurement solutions, offering a range of venturi tubes designed to deliver accurate and reliable flow measurement in various industrial applications. Our venturi tubes are built to meet the highest standards of quality and performance, ensuring efficient operation and long-term reliability.

There are two common types of Venturi tubes: the Venturi Nozzle and the Classical Venturi tube. Both include a convergent inlet section and a divergent outlet section. In the Classical Venturi, the convergent section is a simple truncated cone, while in the Venturi Nozzle, the inlet contour aligns with that of the ISA 1932 flow nozzle.

Features

- Suitable for High Temperature and Pressure

- No Moving Parts

- Low Pressure Loss

- Fabricated from Plate or Machined from Bar/ Forgings

- Flanged or Weld-In Construction

- Pipe Sizes from 50 mm to 1200 mm

- Durable

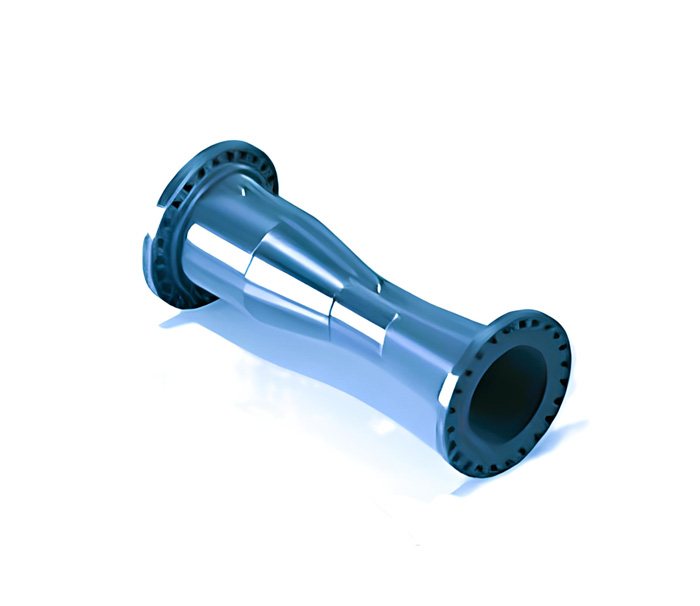

Classical Venturi Tube

Model Number: ARO-VT-C-001

The classical venturi tube features a converging section, throat, and diverging section, enabling highly accurate flow measurement with minimal pressure loss. It is suitable for a wide range of applications, including liquids, gases, and steam.

Applications

- Water and wastewater treatment, power generation, chemical processing, HVAC systems.

Specification

- Material: Stainless Steel 316, Stainless Steel 304, Monel, Hastelloy, Carbon Steel (special alloys on request)

- Connection Sizes: 1/2″ to 48″ (larger sizes on request)

- Pressure Rating: Up to 6000 PSI

- Temperature Rating: -50°F to 1000°F (-45°C to 540°C)

- Accuracy: ±0.5% of reading

- Standards: ISO 5167, ASME MFC-3M, API 2530

- Features: Minimal pressure loss, high accuracy, robust construction

Advantages

- High measurement accuracy with low pressure drop

- Suitable for various fluid types, including liquids, gases, and steam

- Robust design for long-term reliability

- Low maintenance requirements due to its simple construction

Applications

- Industrial fluid measurement systems

- Power plants and steam generation

- HVAC systems for accurate airflow measurement

- Chemical and petrochemical processing plants

Compact Venturi Tube

Model Number: ARO-VT-C-002

The compact venturi tube is designed for applications where space is limited. It offers the same high accuracy as the classical venturi tube but in a more compact form factor.

Applications

- Retrofit installations, process monitoring, space-constrained environments.

Specification

- Material: Stainless Steel 316, Stainless Steel 304, Monel, Hastelloy, Carbon Steel (special alloys on request)

- Connection Sizes: 1/2″ to 24″ (larger sizes on request)

- Pressure Rating: Up to 6000 PSI

- Temperature Rating: -50°F to 1000°F (-45°C to 540°C)

- Accuracy: ±0.5% of reading

- Standards: ISO 5167, ASME MFC-3M, API 2530

- Features: Compact design, high accuracy, easy installation

Advantages

- Space-saving design ideal for compact installations

- Maintains high measurement accuracy

- Easy to install and retrofit into existing systems

Applications

- Retrofit projects in industrial plants

- Monitoring and control in confined spaces

- Applications requiring precise flow measurement in limited space

Venturi Nozzle

Model Number: ARO-VN-003

The venturi nozzle combines the features of a venturi tube and an orifice plate, providing high accuracy flow measurement with a lower pressure drop. It is suitable for applications requiring precise measurement of high-velocity fluids.

Applications

Power plants, steam applications, high-velocity gas measurement.

Specification

- Material: Stainless Steel 316, Stainless Steel 304, Monel, Hastelloy, Carbon Steel (special alloys on request)

- Connection Sizes: 1/2″ to 48″ (larger sizes on request)

- Pressure Rating: Up to 6000 PSI

- Temperature Rating: -50°F to 1200°F (-45°C to 650°C)

- Accuracy: ±0.5% of reading

- Standards: ISO 5167, ASME MFC-3M, API 2530

- Features: Lower pressure drop, high accuracy, robust design

Advantages

- Lower pressure drop compared to other measurement devices

- High accuracy in high-velocity fluid applications

- Durable and robust design for harsh environments

Applications

- High-velocity gas and steam measurement

- Power generation and steam applications

- Industrial processes requiring precise flow measurement

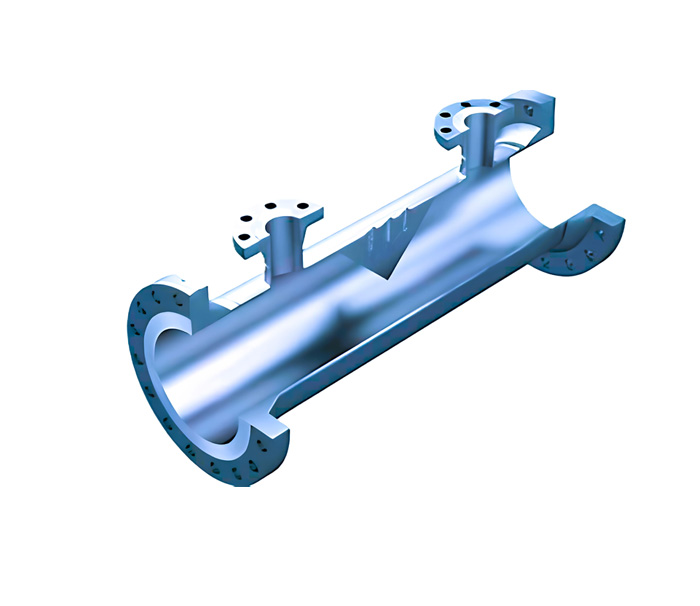

Venturi Cone

Model Number: ARO-VC-004

The venturi cone flow meter features a cone-shaped element that conditions the flow profile, reducing the need for straight upstream piping. It is ideal for applications with limited space and disturbed flow conditions.

Applications

- Oil and gas, chemical processing, industrial gas measurement.

Specification

- Material: Stainless Steel 316, Stainless Steel 304, Monel, Hastelloy, Carbon Steel (special alloys on request)

- Connection Sizes: 1/2″ to 48″ (larger sizes on request)

- Pressure Rating: Up to 6000 PSI

- Temperature Rating: -50°F to 1000°F (-45°C to 540°C)

- Accuracy: ±0.5% of reading

- Standards: ISO 5167, ASME MFC-3M, API 2530

- Features: Reduced need for straight piping, high accuracy, compact design

Advantages

- Ideal for installations with limited straight run requirements

- Accurate measurement in disturbed flow conditions

- Compact design for easy installation in space-constrained areas

Applications

- Oil and gas industry for flow measurement in pipelines

- Chemical processing plants

- Industrial gas flow measurement

Grade

S304, SS316, SS304L, SS316L, Hastelloy C, Monel, IS 2062, AISI 516 GR.60/70. The product can be tailored to accommodate other grades based on specific requests from clients.

Pressure Tappings

Venturis are available with a diverse range of pressure tappings, which can include threaded connections, socket weld connections, and welding nipples.

Isolation valves, condensate chambers, and manifolds can also be provided based on the requirements of the application.

Technical Information

| Parameter | Classical Venturi Tube | Compact Venturi Tube | Venturi Nozzle | Venturi Cone |

|---|---|---|---|---|

| Material | SS 316, SS 304, Monel, Hastelloy | SS 316, SS 304, Monel, Hastelloy | SS 316, SS 304, Monel, Hastelloy | SS 316, SS 304, Monel, Hastelloy |

| Connection Sizes | 1/2″ to 48″ | 1/2″ to 24″ | 1/2″ to 48″ | 1/2″ to 48″ |

| Pressure Rating | Up to 6000 PSI | Up to 6000 PSI | Up to 6000 PSI | Up to 6000 PSI |

| Temperature Rating | -50°F to 1000°F (-45°C to 540°C) | -50°F to 1000°F (-45°C to 540°C) | -50°F to 1200°F (-45°C to 650°C) | -50°F to 1000°F (-45°C to 540°C) |

| Accuracy | ±0.5% of reading | ±0.5% of reading | ±0.5% of reading | ±0.5% of reading |

| Features | Minimal pressure loss, high accuracy, robust construction | Compact design, high accuracy, easy installation | Lower pressure drop, high accuracy, robust design | Reduced need for straight piping, high accuracy, compact design |

These classical Venturi tubes are suitable for use in pipes with diameters ranging from 200 mm to 1,200 mm and with diameter ratios (β) falling between 0.4 and 0.7, inclusive.

Applications of Venturi Tube

- Water Treatment Plants: Venturi tubes are used to measure the flow of water in treatment plants, ensuring accurate dosing of chemicals and optimizing the treatment process.

- Chemical Processing: In chemical plants, Venturi tubes are employed for measuring the flow rates of liquids and gases, aiding in the precise control of chemical processes.

- Oil and Gas Industry: Venturi tubes find applications in the oil and gas sector for measuring the flow of hydrocarbons in pipelines, facilitating efficient transportation and processing.

- HVAC Systems: Venturi tubes are used in heating, ventilation, and air conditioning (HVAC) systems to measure the flow of air and ensure proper ventilation and temperature control in buildings.

- Aerospace Testing: In aerospace applications, Venturi tubes are utilized for aerodynamic testing and analysis, helping measure airspeed and flow characteristics around aircraft components.

- Industrial Ventilation: Venturi tubes play a role in measuring and controlling airflow in industrial ventilation systems, ensuring safe and efficient working conditions.

- Water Supply Networks: Venturi tubes are applied in water supply systems to measure the flow of water, helping utilities manage water distribution and optimize resource usage.

- Power Plants: Venturi tubes are used in power plants to measure the flow rates of various fluids, including cooling water, steam, and fuel, contributing to efficient power generation.

- Environmental Monitoring: Venturi tubes find applications in environmental monitoring systems to measure the flow of gases, aiding in air quality assessments and pollution control.

- Process Industries: Venturi tubes are utilized in various process industries, such as pulp and paper manufacturing, pharmaceuticals, and food processing, for accurate flow rate measurements.

- Testing and Calibration Facilities: Venturi tubes are employed in testing and calibration facilities to ensure accurate measurements of fluid flow rates for different purposes, including the calibration of other flow measurement devices.

- Cleanroom Environments: In cleanroom environments, where maintaining specific air quality standards is critical, Venturi tubes are used to measure and control airflow.

- Petrochemical Industry: Venturi tubes find applications in the petrochemical industry for measuring and monitoring fluid flows in pipelines, contributing to process efficiency and safety.

- Wastewater Treatment: Venturi tubes are employed in wastewater treatment plants to measure the flow of wastewater and optimize treatment processes.

Advantages of Venturi Tube

- High Accuracy: Venturi tubes provide accurate measurements of fluid flow rates due to their well-established design principles and efficient flow profiling.

- Low Pressure Loss: One of the significant advantages of Venturi tubes is their minimal pressure loss compared to other flow measurement devices. The gradual expansion and contraction of the fluid path result in lower energy losses, making them energy-efficient.

- No Moving Parts: Venturi tubes have no moving parts, reducing the risk of mechanical failures and the need for frequent maintenance. This feature enhances their reliability and longevity.

- Durability: The robust design of Venturi tubes, coupled with the absence of moving components, contributes to their durability and longevity. They can withstand harsh operating conditions, including high temperatures and pressures.

- Superior Pressure Recovery: Venturi tubes exhibit superior pressure recovery compared to devices like orifice plates and flow nozzles. A higher percentage of the pressure drop is recovered, reducing energy losses in the system.

- Versatility in Fluids: Venturi tubes can handle a wide range of fluids, including liquids and gases, making them versatile for different industrial applications.

- Cost-Effective: Venturi tubes are often considered cost-effective due to their simple design, longevity, and low maintenance requirements. They provide accurate measurements without the complexity of some alternative flow measurement technologies.

- Ease of Installation: Installing Venturi tubes is relatively straightforward, contributing to their widespread use in various industries.