Orifice plates serve as the predominant primary devices for measuring flow in pipelines by relying on the ‘Differential Pressure’ principle. This principle involves measuring the pressure difference generated when an obstruction is introduced into the fluid flow, resulting from an increase in fluid velocity. Orifice plates are versatile and applicable across a broad spectrum of fluid and operating conditions. They provide a satisfactory level of precision at a minimal cost and offer long-term durability without the need for frequent maintenance.

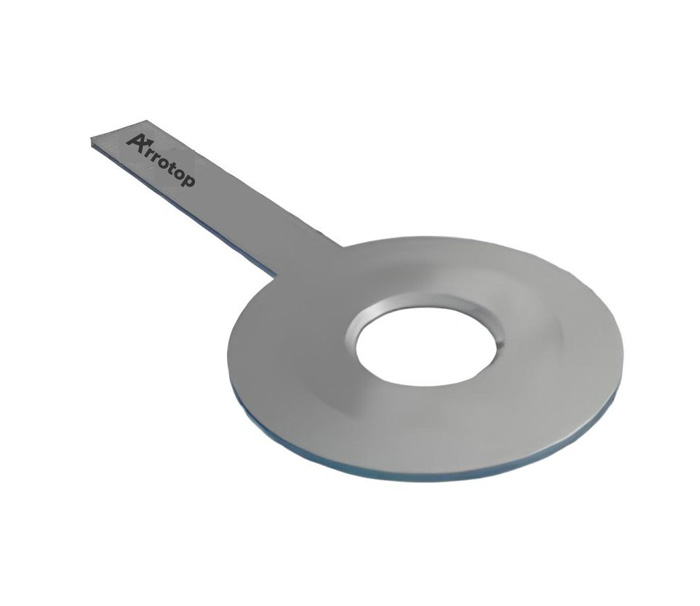

At Arrotop, we specialize in designing and manufacturing high-quality orifice plates tailored to meet diverse industrial needs. Our well-equipped integrated design, manufacturing, and testing facilities rank among the finest in the country. Throughout the years, we have successfully produced and supplied Orifice Plate Assemblies to numerous esteemed projects in both the domestic and international markets. We use advanced manufacturing techniques to ensure each orifice plate meets the highest standards of accuracy and performance. Our orifice plates are available in various materials, including SS 304/L, SS 316/L, Carbon Steel, Duplex Stainless Steel, Super Duplex Stainless Steel, and Alloy Steel, ensuring compatibility with your specific application. We offer a wide range of designs, including Concentric, Eccentric, Segmental, and Quadrant Edge orifice plates, to cater to different industry requirements. Our experts provide guidance on selection, installation, and maintenance, supported by detailed technical specifications and documentation. We tailor our products to your measurement needs, including custom bore sizes, plate thicknesses, and special coatings, along with integrated solutions like Orifice Flange Unions and Orifice Carrier Assemblies. Our commitment to quality and reliability ensures that our products offer consistent and accurate performance for dependable flow measurement.