What is Orifice Plate Assembly?

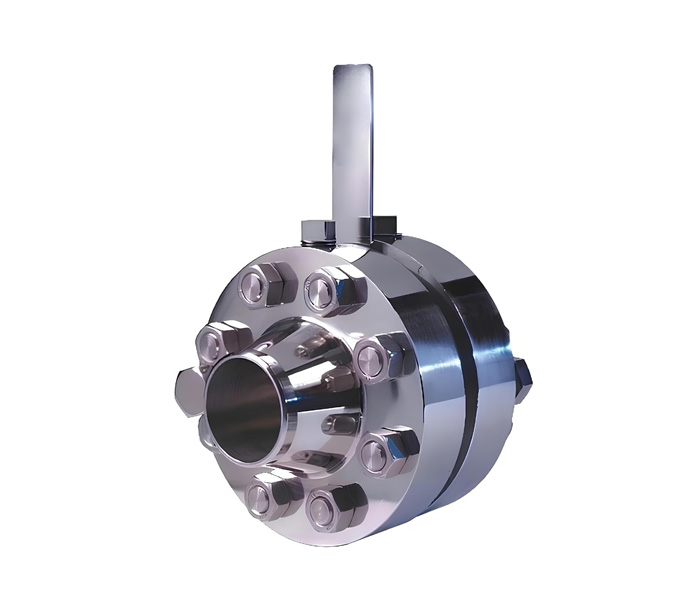

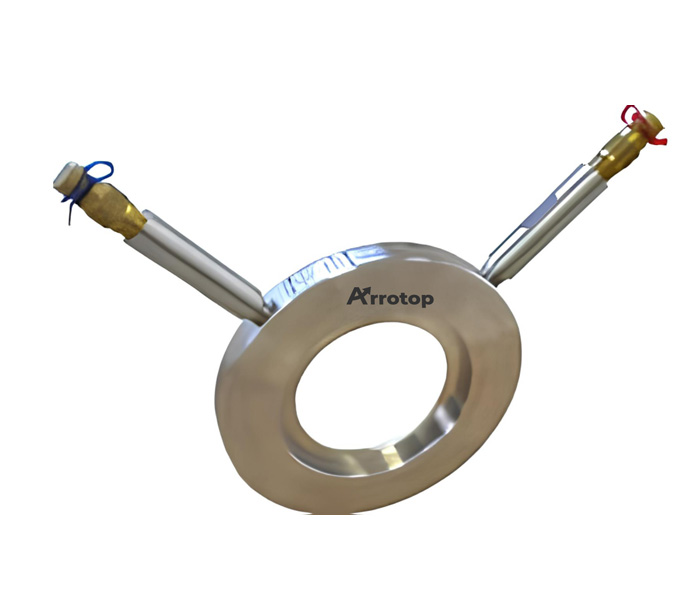

An Orifice Plate Assembly is a device used in fluid mechanics to measure the flow rate of liquids or gases within a pipeline. It comprises a thin, flat plate featuring a central aperture or orifice. This assembly is installed perpendicular to the direction of fluid flow, usually between two flanges in a pipe system. The orifice plate causes a pressure drop as the fluid passes through it, and the difference in pressure is measured to determine the flow rate. Pressure taps are positioned upstream and downstream of the orifice plate to accurately assess this pressure differential. The size and shape of the orifice, along with calculations based on fluid properties, allow for precise flow rate calculations. Orifice Plate Assemblies find widespread use in industries such as oil and gas, chemical processing, and water treatment for their cost-effective and reliable flow measurement capabilities.

Types of Orifice Plate Assembly

Product Data

ARROTOP™ produces cost-effective flow measurement solutions utilizing the principle of differential pressure. These products are suitable for a diverse range of line sizes, pressures, and temperatures, catering to industries such as chemical, petrochemical, oil and gas, refineries, fertilizers, beverages, metal and food, cement, pharmaceuticals, and more.

The orifice plate assembly stands as one of the most commonly employed flow measurement solutions. ARROTOP™ crafts these orifice plates using high-quality materials, adhering closely to standards such as ISO 5167, BS 1042, API 2530, and AGA Report 3. Installation options include mounting between flanges or carrier rings. This orifice plate assembly ensures precise measurements without the need for maintenance.

The design of Orifice Plates and flanges conforms to a variety of international standards, including BS 1042, ISO 5167, ASME MFC 3M, AGA 3, AGA 8, RW MILLAR, L.K. SPINK, among others. Additionally, our forged flanges adhere to international standards such as ANSI, ASME, DIN, JIS, BS, API, and more.

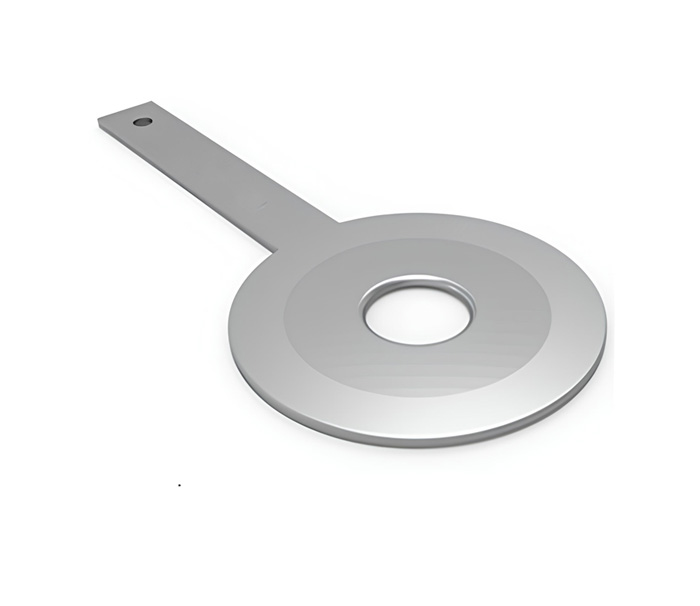

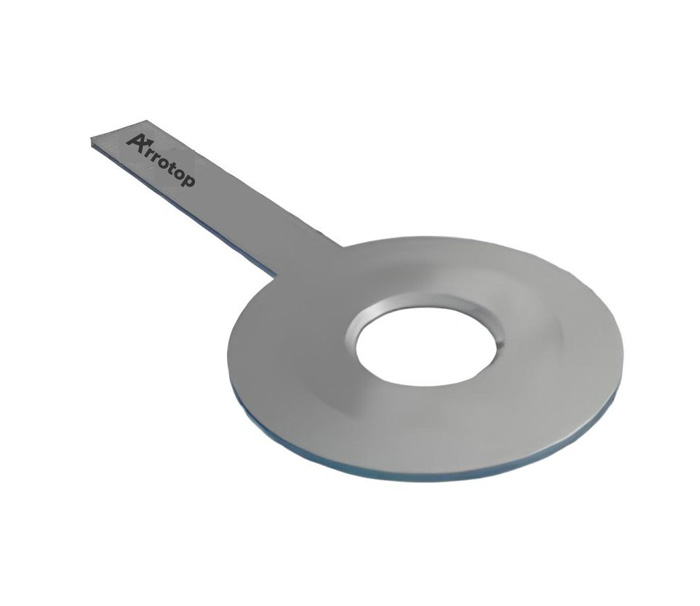

Orifice Plates and Restriction Orifice Plates, with or without a carrier ring, meter run assembly, and integral orifice plates and assemblies.

Orifice Plate Types : Square Edge Concentric, Eccentric, Segmental, Quadrant Edge, Conical Entrance Plates.

Plate thickness : 3.18 mm, 6.35 mm, 9.52 mm, 12.7 mm as standard, other on request.

Plate Material : Standard materials include SS304, SS316, SS304L, and SS316L. Additionally, Hastelloy C, Monel, Inconel, Polypropylene (PP), PVC, PTFE-coated, Stellite-coated, and others are available upon request.

Orifice Flanges : Forged construction orifice flanges are offered in various types, including Weld Neck, Slip On, Threaded, and Socket Weld, featuring RF, FF, RTJ facing. These flanges are rated from 150# to 2500#, and higher ratings are available upon request. The ratings adhere to ASME 16.36 for sizes up to 8″ or male-female flanges in accordance with ASME B 16.5, ASME B 16.47 series A/B.

In the case of RTJ Flanges, the plate is securely positioned within the plate holder, which is softer than the flange and serves as a gasket.

Flange Material : SS316, A105, A182F11, A182F22, PP, PTFE, SS316L, SS304, SS304L, Hastelloy, Monel

Orifice assembly size and rating : ½” to 64” and rating 150# to 2500#

Pressure Tapping : Corner Tappings are advised for sizes up to 1.1/2”, flange taps are recommended for sizes from 2” to 16”, and D – D1/2 Taps are suggested for larger sizes.

Gasket: Compressed Asbestos Fiber (CAF) in accordance with IS:2712 Gr 0/1, Stainless Steel Spiral Wound with CAF, Stainless Steel Spiral Wound with Grafoil, and Stainless Steel Wound with PTFE are typically provided based on process specifications. Alternative materials are available upon request.

Stud / Nuts: We produce studs and nuts in the standard ASTM A193 Grade B7 paired with A-194 Grade 2H, with alternative materials available upon request.

Jack Screw: We produce jack screws in the standard ASTM A193 Grade B7, with alternative materials available upon request.

Testing: PMI, Hydrostatic Testing, Radiography, Flow Calibration, NACE, Post Weld Heat Treatment (PWHT), IBR (Indian Boiler Regulations), Oxygen Cleaning, Dye Penetration Test, Magnetic Particle Test, HIC Test, and other tests are available as needed.

Flow calibration Test Bench : ARROTOP™ has developed an in-house flow calibration bench designed for calibrating flow elements up to a line size of 12″. This calibration is conducted in accordance with the fluid mechanism standards of ISO 5167 and IEC 60534.

Certifications : Certifications include CE, GOST R, and IBR.

| Design | Conforms to ISA RP 3.2, DIN 1952, BS 1042, ISO 5167, ASME MFC-3M |

|---|---|

| Types | Square Edge Concentric, Quadrant Edged, Conical Entrance, Eccentric, Segmental |

| Plate Material | AISI SS 316 as standard. SS 304, SS 316L, Hastelloy-C, Monel, PP, PVC, PTFE, coated etc. can be given on request. |

| Orifice Bore | In accordance with ISO 5167, BS 1042, ASME MFC 3M, R.W. Miller, L.K. Spink, AGA-3 |

| Tag Plate | In the same material as Plate & is welded to orifice plate. Tag plate integral to the orifice plate (i.e. without welding) can also be offered as a special case. |

| Vent / Drain | Vent or Drain holes are provided as per customer’s requirement. |

| Flange Type | Weld Neck, Slip On, Threaded, Socket welded with RF or RTJ facing orifice flanges are in accordance with ASME B16.36 with minimum flange rating of 300# |

| Flange Material | ASTM A 105 as standard, ASTM A182 F11, ASME ASTM A 350, ASTM A 182 F316, ASTM A182 F304, ASTM A 182 F 316L, ASTM A 182 F 304L, FRVE etc. |

| Pressure Tappings | Corner tappings are recommended for sizes upto 1 ½”, flange taps from 2” onwards |

| Gasket | SS spiral wound + Grafoil, SS spiral wound + PTFE are normally supplied as per process requirement. Other materials Available on request. For RTJ flanges, the plate is fixed on the plate holder. The plate holder is in soft iron material & acts as a gasket. |

| Studs / Nuts | ASTM A 193, Gr. B7/A-194 Gr. 2H as standard, Other material on request. |

Applications of Orifice Plate Assembly:

- Oil and Gas Industry: Orifice plate assemblies are commonly used in the oil and gas sector for measuring the flow rates of crude oil, natural gas, and refined products. They are applied in pipelines, refineries, and distribution systems.

- Chemical Industry: Orifice plate assemblies find applications in chemical processing plants for measuring and controlling the flow rates of liquids and gases. They are used in processes such as mixing, dosing, and distribution of chemicals.

- Water and Wastewater Treatment: Orifice plate assemblies are employed in water treatment plants to measure the flow rates of water and various chemicals involved in treatment processes. They also find use in wastewater treatment for monitoring and controlling effluent flow.

- HVAC Systems: Orifice plate assemblies are utilized in heating, ventilation, and air conditioning (HVAC) systems to measure the flow rates of air and other fluids. They contribute to maintaining proper air circulation and temperature control in buildings.

- Power Generation: Orifice plate assemblies are applied in power plants to measure the flow rates of steam, cooling water, and other fluids. They play a role in processes such as turbine control, boiler feedwater, and condenser water systems.

- Pulp and Paper Industry: Orifice plate assemblies find applications in the pulp and paper industry for measuring the flow rates of various liquids and chemicals involved in the paper manufacturing process, including pulp slurries and chemicals for paper treatment.

- Mining Industry: Orifice plate assemblies are used in the mining sector for measuring the flow rates of water, slurries, and other fluids in extraction and processing operations.

- Aerospace Industry: In the aerospace sector, orifice plate assemblies are employed for measuring the flow rates of fuel and other fluids in aircraft propulsion systems.

- Food and Beverage Industry: Orifice plate assemblies are applied in the food and beverage industry for measuring and controlling the flow rates of liquids in various production processes, including mixing, filling, and packaging.

- Automotive Industry: Orifice plate assemblies are used in the automotive sector for measuring the flow rates of fluids such as fuel and coolant in engines and hydraulic systems.

- General Industrial Processes: Orifice plate assemblies are employed in a wide range of general industrial processes where accurate flow measurement is essential for process control, optimization, and efficiency.

Advantages of Orifice Plate Assembly:

- Cost-Effectiveness: Orifice plate assemblies are generally cost-effective compared to some other flow measurement devices. The simplicity of their design and the materials used contribute to their affordability.

- Simplicity and Ease of Installation: The design of orifice plate assemblies is relatively simple, making them easy to install. They can be easily mounted in a pipeline, and the installation process is straightforward.

- Low Maintenance: Orifice plate assemblies have minimal moving parts, resulting in low maintenance requirements. Regular inspection and occasional cleaning are typically sufficient to maintain their performance.

- Versatility: Orifice plate assemblies can be used for measuring the flow of various fluids, including liquids, gases, and steam. This versatility makes them suitable for a wide range of industrial applications.

- Wide Range of Pipe Sizes: Orifice plate assemblies are available in various sizes, making them adaptable to different pipe diameters and flow rates. This flexibility enhances their applicability in diverse industrial settings.

- Accuracy: When properly designed, installed, and calibrated, orifice plate assemblies can provide accurate measurements of fluid flow rates. This accuracy is crucial for processes where precise flow control is necessary.

- Standardization: Orifice plate assemblies are often manufactured following industry standards, such as those outlined by organizations like the American National Standards Institute (ANSI) or the International Organization for Standardization (ISO). This standardization ensures consistency and compatibility across different systems.

- Proven Reliability: Orifice plate assemblies have a long history of reliable performance in various industrial applications. Their established track record attests to their dependability.

- Integral Design Options: Orifice plate assemblies can be integrated into other measurement devices or systems, providing a comprehensive solution for flow measurement and control in industrial processes.

- Applicability in High-Pressure Systems: Orifice plate assemblies can be designed to withstand high-pressure conditions, making them suitable for applications where fluid flow measurements are required in challenging environments.

- Compatibility with Various Materials: Orifice plate assemblies can be constructed from different materials, allowing users to select a material that is compatible with the characteristics of the fluid being measured and the surrounding environment.

- Energy Efficiency: Orifice plate assemblies typically result in lower permanent pressure loss compared to some other flow measurement devices, contributing to energy efficiency in the overall system.