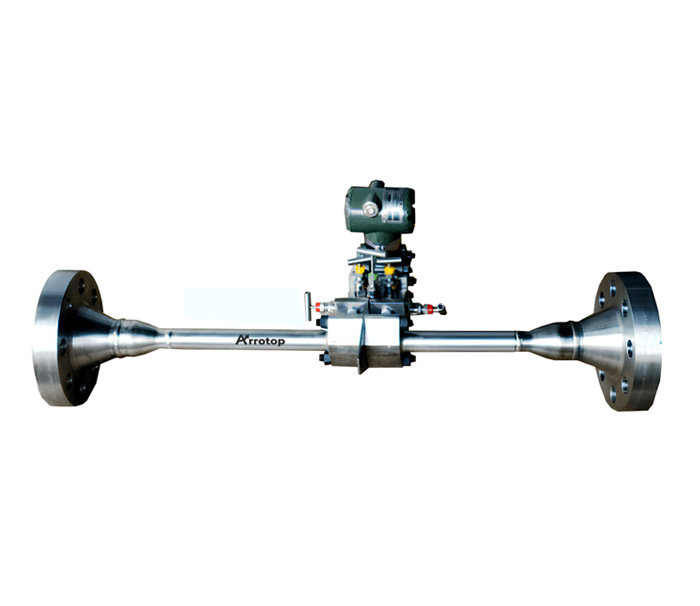

The integral flow orifice assembly is employed for pipe sizes of 2″ and below. However, due to the temperature limitations of the transmitter, this assembly cannot be utilized for process temperatures exceeding 120 degrees Celsius (248 degrees Fahrenheit).

The assembly comprises an orifice plate positioned between two integral blocks with corner taps. It is typically advisable to use a meter run pipe with an upstream length of 750 mm and a downstream length of 250 mm.

The blocks are affixed to the pipes using end flanges. The entire flow measuring system comprises an integral orifice assembly, manifold, and DP transmitter. Our in-house calibration facility is available for calibrating the integral orifice assemblies we produce, and calibration services can be provided upon customer request. These integral assemblies are available in materials such as CS, SS316, SS304, and others upon specific request.