• ARO-FN-ISA-001 • ARO-FN-LR-002

• ARO-FN-HV-003

What is Flow Nozzle?

A flow nozzle serves as a specialized primary flow element suitable for high-velocity and high-pressure conditions involving non-viscous and erosive fluids, where the use of orifice plates may lead to wear or damage. Flow nozzles can be seamlessly integrated into pre-assembled meter runs, mounted between flanges, or welded directly into the pipe. They necessitate less straight upstream piping and result in lower permanent pressure loss compared to orifice plates. Additionally, flow nozzles eliminate the exposure of sharp edges prone to wear. Various types of flow nozzles are available, such as the throat tap long-radius ASME PTC 6 nozzle, commonly utilized for the performance testing of steam turbines.

Arrotop’s range of flow nozzles offers reliable and accurate flow measurement solutions tailored to meet the demands of various industrial applications. Our models ensure high accuracy, robust construction, and long-term reliability, making them ideal for a wide range of industries.

Product Data

Arrotop is a trusted provider of high-precision flow measurement solutions, including a comprehensive range of flow nozzles. Our flow nozzles are designed for accurate and reliable flow measurement in various industrial applications, adhering to international standards and ensuring long-term performance.

Arrotop’s Flow Nozzles are engineered for applications that require precise flow measurement under a range of conditions. These nozzles are built to withstand high-pressure and high-temperature environments, making them suitable for demanding industrial processes. Their design ensures minimal pressure drop and high accuracy, adhering to international standards like ISO 5167 and ASME MFC-3M.

The flow nozzle is designed according to Bernoulli’s equation, featuring a convergent section with a rounded profile and a cylindrical throat. Its dimensional stability at elevated temperatures and flow rates exceeds that of an orifice, thanks to its inherent rigidity.

The flow nozzle is commonly employed to measure the flow of steam and non-viscous, erosive, and high-velocity media. Its applications span a wide range, including steam, air, water, vapor, gas, chemical substances, and high temperatures. In instances involving erosive media, a hardened internal surface option is available.

The design and production of the flow nozzles adhere to ISO 5167 standards, ensuring an accuracy of ±1.0%. Through calibration, even higher precision of up to ±0.25% can be attained.

To minimize pressure loss, a Venturi nozzle can be provided, incorporating the typical characteristics of a flow nozzle along with a divergent section.

Features

- The ideal choice for accurately measuring steam flow under conditions of elevated pressure, high temperature, and high velocity.

- Differential Pressure Measurement

- The assembly’s stability is greatly enhanced by its smooth profile and robust structure.

- Applicable for measuring the flow of liquids, gases, and steam.

- Accuracy ≤ ±0.1 % of actual flow rate

- Maintenance-free due to the absence of any moving parts.

Flow Nozzle Types

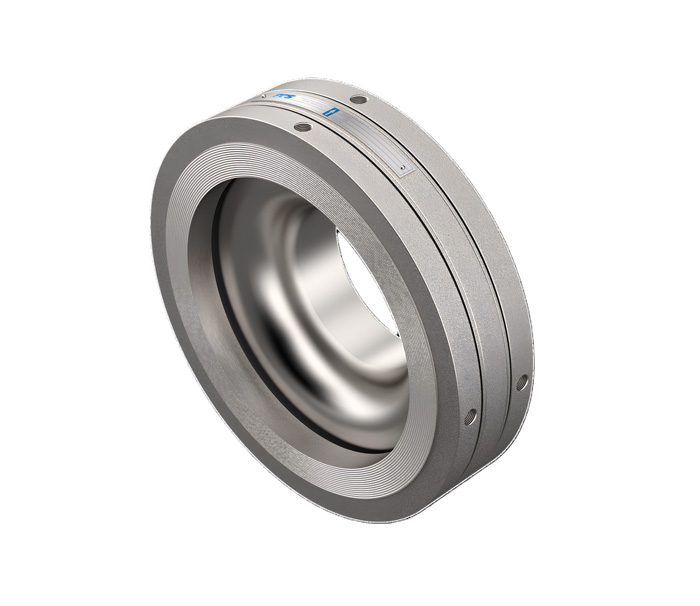

The ISA 1932 nozzle

The interior of the pipe’s nozzle is circular, comprising a rounded convergent section and a cylindrical throat.

This nozzle variant should adhere strictly to the specifications outlined in this section of ISO 5167, applicable when 50 mm ≤ D ≤ 500 mm & 0, 3 ≤ β ≤ 0, 8.

Model Number: ARO-FN-ISA-001

Description

The ISA 1932 flow nozzle is designed according to the International Society of Automation (ISA) standard ISA 1932. It features a long radius and is ideal for applications requiring high accuracy and repeatability.

Applications

Power generation, chemical processing, water and wastewater treatment, and steam applications.

Specification

- Material: Stainless Steel 316, Stainless Steel 304, Monel, Hastelloy, Carbon Steel (special alloys on request)

- Connection Sizes: 1/2″ to 36″ (larger sizes on request)

- Pressure Rating: Up to 6000 PSI

- Temperature Rating: -50°F to 1200°F (-45°C to 650°C)

- Accuracy: ±0.5% of reading

- Standards: ISA 1932, ISO 5167, ASME MFC-3M

- Features: High accuracy, repeatable performance, robust construction

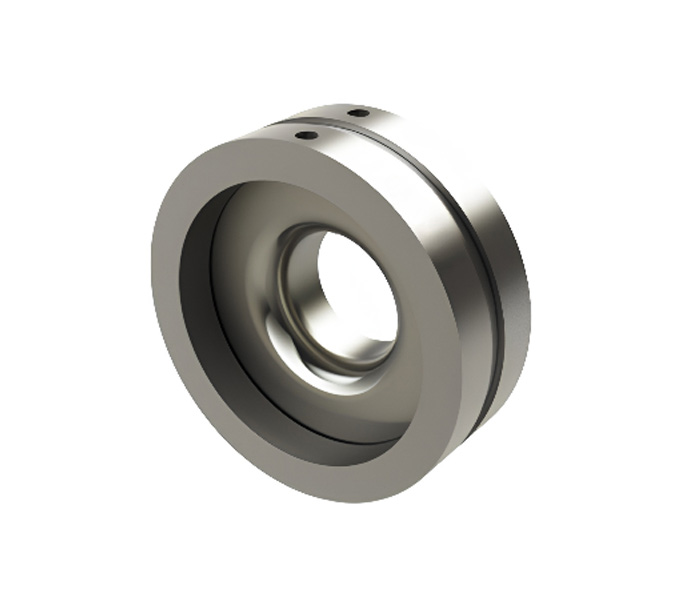

The Long Radius Nozzle

There are two categories of long-radius nozzles, commonly referred to as:

1) high-ratio nozzles (0, 25 u β u 0, 8), and

2) low-ratio nozzles (0, 20 u β u 0, 5).

The long radius nozzles are to be exclusively used in accordance with ISO 5167 when 50 mm ≤ D ≤ 630 mm 0, 2 ≤ β ≤ 0, 8

Model Number: ARO-FN-LR-002

Description

The long radius flow nozzle features an extended radius design, reducing the impact of flow disturbances and providing stable flow measurement. It is suitable for high-velocity fluid measurements.

Applications

Steam flow measurement, high-velocity gas measurement, and power plants.

Specification

- Material: Stainless Steel 316, Stainless Steel 304, Monel, Hastelloy, Carbon Steel (special alloys on request)

- Connection Sizes: 1/2″ to 36″ (larger sizes on request)

- Pressure Rating: Up to 6000 PSI

- Temperature Rating: -50°F to 1200°F (-45°C to 650°C)

- Accuracy: ±0.5% of reading

- Standards: ISO 5167, ASME MFC-3M, API 2530

- Features: Reduced flow disturbances, high accuracy, durable design

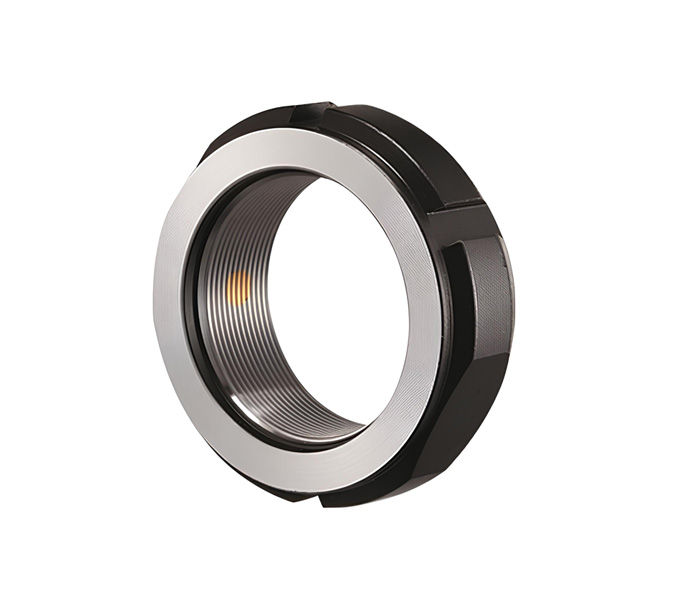

High-Velocity Flow Nozzle

Model Number: ARO-FN-HV-003

Description

Designed for high-velocity applications, this flow nozzle ensures accurate measurement under extreme conditions. Its robust design makes it ideal for use in demanding industrial environments.

Applications

High-velocity steam and gas applications, chemical processing, and petrochemical industries.

Specification

- Material: Inconel, Hastelloy, Stainless Steel 316 (special alloys on request)

- Connection Sizes: 1/2″ to 36″ (larger sizes on request)

- Pressure Rating: Up to 6000 PSI

- Temperature Rating: -50°F to 1500°F (-45°C to 815°C)

- Accuracy: ±0.5% of reading

- Standards: ISO 5167, ASME MFC-3M, API 2530

- Features: Suitable for high-velocity applications, high accuracy, robust construction

Grade – S304, SS316, SS304L, SS316L, Hastelloy C, Monel, IS 2062, AISI 516 GR.60/70. The product can be tailored to accommodate other grades based on specific requests from clients.

Technical Information

| Parameter | ISA 1932 Flow Nozzle | Long Radius Flow Nozzle | High-Velocity Flow Nozzle |

|---|---|---|---|

| Material | SS 316, SS 304, Monel, Hastelloy | SS 316, SS 304, Monel, Hastelloy | Inconel, Hastelloy, SS 316 |

| Connection Sizes | 1/2″ to 36″ | 1/2″ to 36″ | 1/2″ to 36″ |

| Pressure Rating | Up to 6000 PSI | Up to 6000 PSI | Up to 6000 PSI |

| Temperature Rating | -50°F to 1200°F (-45°C to 650°C) | -50°F to 1200°F (-45°C to 650°C) | -50°F to 1500°F (-45°C to 815°C) |

| Accuracy | ±0.5% of reading | ±0.5% of reading | ±0.5% of reading |

| Standards | ISA 1932, ISO 5167, ASME MFC-3M | ISO 5167, ASME MFC-3M, API 2530 | ISO 5167, ASME MFC-3M, API 2530 |

| Features | High accuracy, repeatable performance, robust construction | Reduced flow disturbances, high accuracy, durable design | Suitable for high-velocity applications, high accuracy, robust construction |

Applications of Flow Nozzle

- Oil and Gas Industry: Flow nozzles are used in the oil and gas sector for measuring the flow rates of crude oil, natural gas, and various refined products. They are employed in pipelines, refineries, and petrochemical plants.

- Chemical Industry: Flow nozzles play a crucial role in measuring the flow of chemicals and chemical processes. They are used in chemical manufacturing plants to monitor and control the flow of liquids and gases.

- Power Generation: Flow nozzles are used in power plants, including both conventional and renewable energy facilities. They help measure the flow of water, steam, or other fluids in processes such as cooling water systems, boiler feedwater, and steam turbines.

- Water and Wastewater Treatment: Flow nozzles are utilized in water treatment plants to measure the flow rates of water and various chemicals. They are also used in wastewater treatment processes to monitor the flow of effluent.

- HVAC Systems: Flow nozzles can be used in heating, ventilation, and air conditioning (HVAC) systems to measure the flow rates of air or other fluids. They help ensure proper ventilation and temperature control in buildings.

- Aerospace Industry: In the aerospace sector, flow nozzles are used for measuring the flow rates of fuel, lubricants, and other fluids in aircraft and rocket propulsion systems.

- Steam Systems: Flow nozzles are commonly employed in steam systems to measure the flow rates of steam. This is crucial for controlling processes in industries such as manufacturing, food processing, and power generation.

- Automotive Industry: Flow nozzles can be used in automotive applications to measure the flow rates of liquids, such as fuel or coolant, in engines and other systems.

- Research and Development: Flow nozzles are used in research and development settings where accurate flow measurements are required for experimental setups and testing procedures.

- Pulp and Paper Industry: In the pulp and paper industry, flow nozzles are utilized to measure the flow rates of various liquids and chemicals involved in the paper manufacturing process.

- Mining Industry: Flow nozzles find applications in the mining industry for measuring the flow rates of water, slurries, and other fluids used in extraction and processing operations.

- Food and Beverage Industry: Flow nozzles are employed in the food and beverage industry to measure the flow rates of liquids in production processes, including the handling of ingredients, mixing, and packaging.

Advantages of Flow Nozzle

- High Accuracy: Flow nozzles are known for their high level of accuracy in measuring flow rates. The design of the nozzle provides a stable and well-defined relationship between the flow rate and the pressure drop across the nozzle.

- Wide Range of Applications: Flow nozzles can be used for various fluids, including liquids, gases, and steam. This versatility makes them suitable for a broad range of industrial applications in fields such as petrochemical, chemical, power generation, and water treatment.

- Robust and Durable: Flow nozzles are typically robust and durable, making them suitable for harsh operating conditions. They are often constructed from materials such as stainless steel or other corrosion-resistant alloys, ensuring a long service life.

- Low Maintenance: With a simple design and no moving parts, flow nozzles generally require minimal maintenance. This low maintenance requirement contributes to their reliability and cost-effectiveness over time.

- Stable Performance: Flow nozzles provide stable and repeatable performance over a wide range of flow conditions. This stability is crucial for consistent and reliable flow measurements.

- Cost-Effective: Compared to some other flow measurement devices, flow nozzles can be cost-effective both in terms of initial installation and long-term maintenance. Their simplicity and reliability contribute to overall cost savings.

- Versatility in Flow Conditions: Flow nozzles can handle a wide range of flow conditions, including both high and low flow rates. This versatility makes them suitable for applications with varying flow requirements.

- Temperature and Pressure Compatibility: Flow nozzles are designed to operate within specific temperature and pressure ranges. Manufacturers provide specifications that indicate the maximum allowable values for these parameters, ensuring compatibility with various industrial processes.

- Minimal Pressure Loss: Flow nozzles typically result in lower pressure loss compared to some other flow measurement devices. This is advantageous in systems where minimizing pressure drop is important.