• ARO-CFM-STD-001 • ARO-CFM-HT-002

• ARO-CFM-IM-003

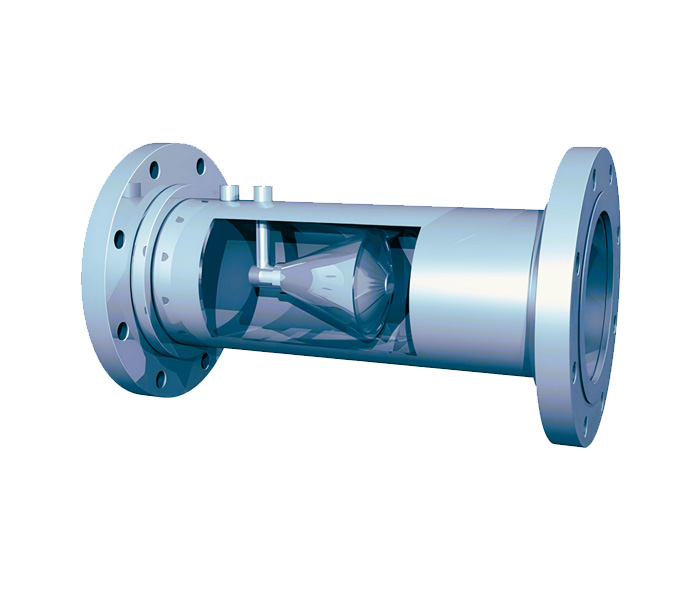

What is Cone Flowmeter?

A flow meter is a type of differential pressure flowmeter designed for the precise measurement of liquids, steam, or gases, even in challenging operating conditions. It serves as a process control and fluid flow measurement instrument, offering an accurate, repeatable, and cost-effective solution for measuring flow rates.

Arrotop’s cone flowmeters offer high precision, durability, and versatility for various industrial applications. Trust Arrotop for reliable flow measurement solutions tailored to your needs.

Product Data

Arrotop’s Cone Flowmeters are engineered for applications that require precise flow measurement under challenging conditions. These flowmeters feature a centrally positioned cone that reshapes the flow profile, enhancing accuracy and reducing sensitivity to installation. They are ideal for applications with limited straight pipe runs and demanding environmental conditions.

Arrotop Averaging Pitot tubes equipped with multiple sensing ports constantly average the flow profile, producing a differential pressure that accurately reflects the mean flow rate within the pipeline.

Arrotop Averaging Pitot Tubes provide precise measurements with a low permanent pressure loss, usually less than 10% of the differential pressure (DP). There are two measurement principles and designs. High Flow tubes feature a single static pressure port located outside the flowing fluid area, leading to a reduced DP. This design allows for sustained accuracy across a broader turn-down range and at higher flow rates.

Low Flow variants incorporate dual ports situated within the flowing region. This positioning creates a suction effect at the ports, amplifying the available range of differential pressure. This feature allows the Averaging Pitot Tube to be effectively employed in low-velocity systems.

Arrotop provides the Averaging Pitot Tube design tailored to accommodate various pipe-work configurations, offering different connections and orientations. Our comprehensive engineering support spans from the initial design and sizing concepts to the manufacturing of the final products.

Types of Cone Flowmeters

Standard Cone Flowmeter

Model Number: ARO-CFM-STD-001

Description

The standard cone flowmeter is engineered with a centrally positioned cone that reshapes the flow profile, enhancing accuracy and reducing installation sensitivity.

Applications

Oil and gas, chemical processing, power generation, and water treatment.

Specification

- Material: Stainless Steel 316, Stainless Steel 304, Monel, Hastelloy, Carbon Steel (special alloys on request)

- Connection Sizes: 0.5″ to 24″ (larger sizes on request)

- Pressure Rating: Up to 6000 PSI

- Temperature Rating: -50°F to 1000°F (-45°C to 540°C)

- Accuracy: ±0.5% of reading

- Standards: ISO 5167-6, ASME MFC-3M, API 2530

- Features: High accuracy, robust construction, minimal straight pipe requirements

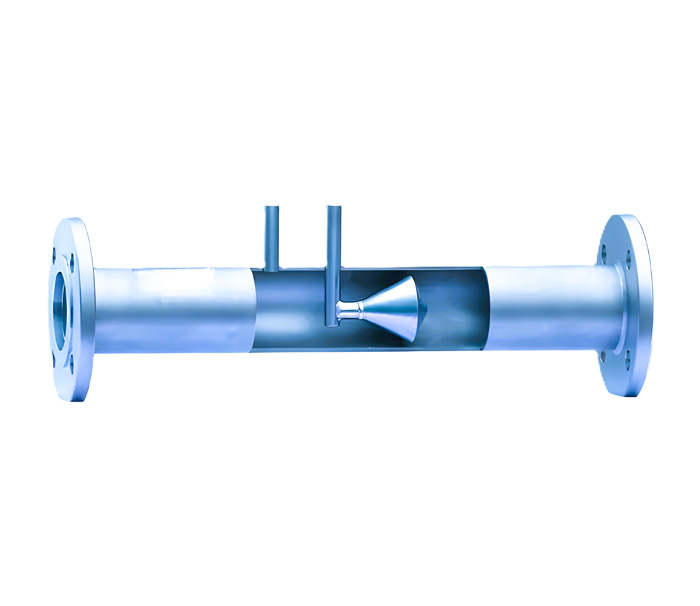

High Temperature Cone Flowmeter

Model Number: ARO-CFM-HT-002

Description

This model is specifically designed for high-temperature applications, ensuring accurate flow measurements in extreme thermal conditions.

Applications

Power plants, petrochemical industries, and high-temperature fluid processes.

Specification

- Material: Inconel, Hastelloy, Stainless Steel 316 (special alloys on request)

- Connection Sizes: 0.5″ to 24″ (larger sizes on request)

- Pressure Rating: Up to 6000 PSI

- Temperature Rating: -50°F to 1500°F (-45°C to 815°C)

- Accuracy: ±0.5% of reading

- Standards: ISO 5167-6, ASME MFC-3M, API 2530

- Features: High-temperature resistance, high accuracy, robust construction

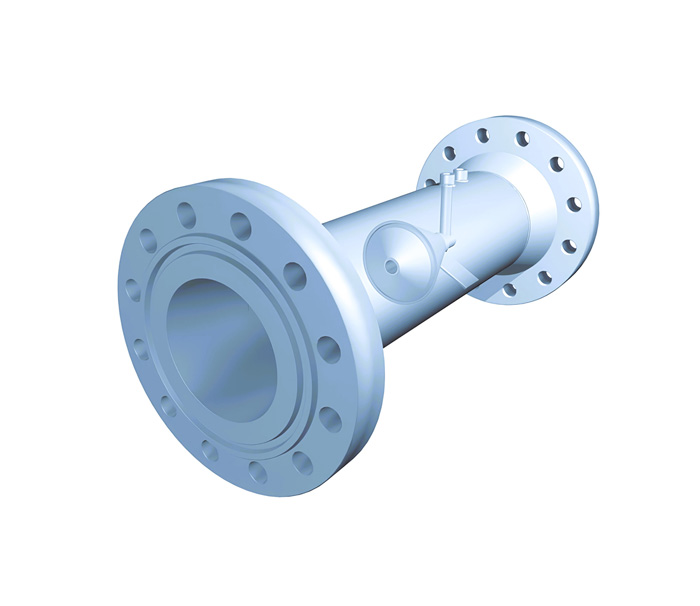

Insertion Cone Flowmeter

Model Number: ARO-CFM-IM-003

Description

The insertion cone flowmeter allows for easy installation and maintenance without process interruption, ideal for retrofit projects and continuous monitoring.

Applications

Industrial process monitoring, water and wastewater management, and retrofit installations.

Specifications :

- Material: Stainless Steel 316, Stainless Steel 304, Monel, Hastelloy, Carbon Steel (special alloys on request)

- Connection Sizes: 0.5″ to 24″ (larger sizes on request)

- Pressure Rating: Up to 6000 PSI

- Temperature Rating: -50°F to 1000°F (-45°C to 540°C)

- Accuracy: ±0.5% of reading

- Standards: ISO 5167-6, ASME MFC-3M, API 2530

- Features: Easy installation/removal, high accuracy, suitable for retrofit installations

Features :

- Suitable for liquid, gas and steam flow measurement

- Low permanent pressure loss

- Low installation cost

- Suitable for large pipes and ducts

- Wide flow turn down

- Long term accuracy

- Minimal unrecovered pressure loss

Technical Information

| Parameter | Standard Cone Flowmeter | High Temperature Cone Flowmeter | Insertion Cone Flowmeter |

|---|---|---|---|

| Material | SS 316, SS 304, Monel, Hastelloy | Inconel, Hastelloy, SS 316 | SS 316, SS 304, Monel, Hastelloy |

| Connection Sizes | 0.5″ to 24″ | 0.5″ to 24″ | 0.5″ to 24″ |

| Pressure Rating | Up to 6000 PSI | Up to 6000 PSI | Up to 6000 PSI |

| Temperature Rating | -50°F to 1000°F (-45°C to 540°C) | -50°F to 1500°F (-45°C to 815°C) | -50°F to 1000°F (-45°C to 540°C) |

| Accuracy | ±0.5% of reading | ±0.5% of reading | ±0.5% of reading |

| Standards | ISO 5167-6, ASME MFC-3M, API 2530 | ISO 5167-6, ASME MFC-3M, API 2530 | ISO 5167-6, ASME MFC-3M, API 2530 |

| Features | High accuracy, robust construction, minimal straight pipe requirements | High-temperature resistance, high accuracy, robust construction | Easy installation/removal, high accuracy, suitable for retrofit installations |

Applications of Cone Flowmeter

- Oil and Gas Industry: Cone flowmeters are utilized in upstream, midstream, and downstream operations within the oil and gas industry. They are employed for measuring the flow rates of crude oil, natural gas, refined petroleum products, and various hydrocarbon fluids in pipelines, wellheads, and refineries. Cone meters provide accurate measurements even in challenging conditions such as high pressures, temperatures, and varying fluid viscosities.

- Chemical Processing: In chemical plants and refineries, cone flowmeters are used to measure the flow rates of corrosive chemicals, solvents, and process fluids. Their robust construction and resistance to corrosion make them suitable for handling aggressive media and ensuring accurate process control.

- Water and Wastewater Treatment: Cone flowmeters are widely employed in water treatment plants, wastewater facilities, and desalination plants for measuring the flow rates of water, sewage, and other liquids. They help in optimizing the efficiency of treatment processes, monitoring water usage, and ensuring compliance with regulatory standards.

- Power Generation: Within power plants, cone flowmeters are installed in boiler feedwater systems, cooling water circuits, and steam lines for measuring the flow rates of water, steam, and other fluids. Accurate flow measurement is essential for efficient power generation, turbine performance monitoring, and plant safety.

- Pulp and Paper Industry: Cone flowmeters are used in pulp and paper mills for measuring the flow of pulp slurries, chemicals, and process fluids. They help in controlling the production process, optimizing pulp consistency, and ensuring efficient use of resources.

- Mining and Minerals: In mining operations, cone flowmeters are employed for measuring the flow rates of slurries containing minerals, ores, and abrasive solids. They help in monitoring the efficiency of mineral processing equipment, controlling the extraction process, and minimizing downtime due to equipment failures.

- Food and Beverage: Within the food and beverage industry, cone flowmeters are used for measuring the flow rates of ingredients, beverages, and process fluids. They ensure accurate dosing, mixing, and batching in food processing, brewing, and bottling operations.

- HVAC Systems: Cone flowmeters are integrated into heating, ventilation, and air conditioning (HVAC) systems for measuring the flow rates of chilled water, hot water, and refrigerants. They help in optimizing energy consumption, maintaining comfort levels, and ensuring efficient operation of HVAC equipment in commercial and residential buildings.

Advantages of Cone Flowmeter

- Accuracy: Cone Flowmeters provide accurate and reliable flow measurements, making them suitable for applications where precise monitoring is crucial.

- Wide Rangeability: These flowmeters exhibit good rangeability, meaning they can measure a broad range of flow rates with consistent accuracy.

- Low Permanent Pressure Loss: Cone Flowmeters typically result in low permanent pressure loss, contributing to energy savings and efficient system operation.

- Versatility: Suitable for measuring liquids, gases, and steam, Cone Flowmeters are versatile instruments that can be applied in various industries.

- Resistance to Wear: The design of Cone Flowmeters minimizes wear on critical metering surfaces, leading to a longer service life and reduced maintenance requirements.

- Compact Design: Many Cone Flowmeters are available in compact configurations, making them suitable for applications with limited space.

- Suitability for Challenging Conditions: Cone Flowmeters can handle challenging fluid conditions, including high-viscosity fluids, slurries, and fluids containing suspended solids.

- Cost-Effective Solution: These flowmeters offer a cost-effective flow measurement solution, especially considering their durability and low maintenance requirements.

- Minimal Straight Pipe Requirements: Cone Flowmeters often require shorter upstream and downstream straight pipe lengths compared to some other flow measurement devices.

- Special Features: Some Cone Flowmeters may come equipped with additional features, such as taps with condensate chambers and shut-off valves.

- Longevity: The robust design of Cone Flowmeters, coupled with their resistance to wear, contributes to their long service life.