What are Butterfly Valves?

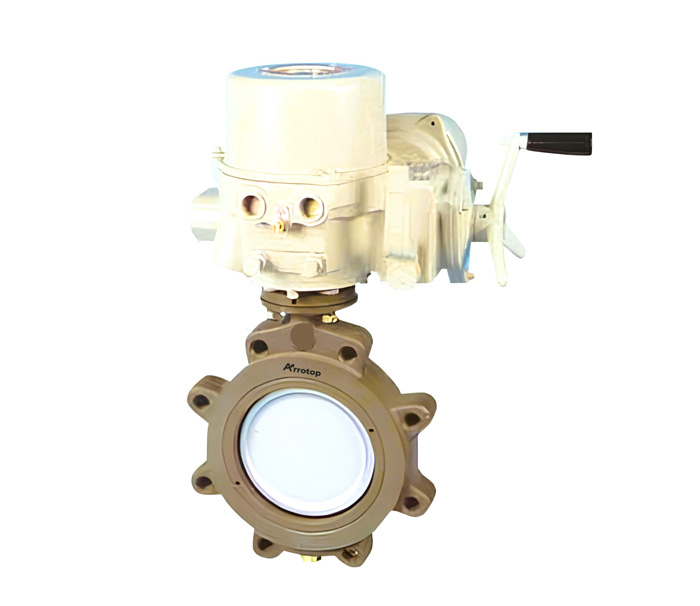

Arrotop Butterfly valves are a type of quarter-turn rotational motion valves used to control the flow of fluids, typically liquids or gases, through a pipe or a duct. The valve’s operation involves a flat, circular disc, known as the “butterfly,” which is mounted on a rod. The disc is positioned in the center of the pipe or duct and can be rotated 90 degrees to either allow or block the flow of the fluid.

Arrotop Butterfly Valves offer reliable and precise flow control solutions tailored to meet the demands of various industrial applications. With a focus on quality and innovation, Arrotop delivers products that ensure superior performance and longevity.

Product Data

OVERVIEW

DIMENSIONAL DATA

APPLICATIONS

ADVANTAGES

OVERVIEW

Arrotop Butterfly Valves are designed for precise control and shutoff of fluid flow. These valves are ideal for applications requiring quick operation and reliable sealing, suitable for water treatment, oil and gas, chemical processing, and more.

A butterfly valve is a type of quarter-turn rotational motion valve utilized to stop, regulate and initiate the flow. A full closure or opening of the valve can be achieved with a simple 90° rotation of the handle. In the case of larger butterfly valves, a gearbox, connecting the handwheel to the stem via gears, is commonly employed. While this gearbox enhances the ease of operation, it does so at the cost of speed.

Butterfly valves typically consist of a compact circular body, a round disc, seats made of either metal-to-metal or soft materials, top and bottom shaft bearings, and a stuffing box. The construction of the butterfly valve body can vary, with one commonly used design being the wafer type, which fits snugly between two flanges. Another design is the lug wafer type, which is held between two flanges using bolts that pass through holes in the valve’s outer casing and join the two flanges. Butterfly valves are also manufactured with flanged, threaded, and butt welding ends, although these options are not as commonly employed.

Butterfly valves offer numerous advantages when compared to gate, globe, plug, and ball valves, particularly in large valve applications. The most evident benefits include savings in weight, space, and cost. Additionally, maintenance costs are typically low due to the limited number of moving parts, and the absence of pockets that can trap fluids further contributes to the efficiency and reliability of butterfly valves.

Butterfly valves are particularly well-suited for managing substantial flows of liquids or gases under relatively low pressures. They are also effective in handling slurries or liquids containing significant amounts of suspended solids.

Butterfly valves are constructed based on the principle of a pipe damper. The flow control element is a disk, roughly matching the inside diameter of the adjacent pipe, and it rotates on either a vertical or horizontal axis. In the fully opened position, the disk aligns parallel to the piping run, allowing unrestricted flow.

Butterfly valves are constructed based on the principle of a pipe damper. The flow control element is a disk, roughly matching the inside diameter of the adjacent pipe, and it rotates on either a vertical or horizontal axis. In the fully opened position, the disk aligns parallel to the piping run, allowing unrestricted flow. As the disk approaches a perpendicular position, the valve closes. Intermediate positions, used for throttling purposes, can be maintained by handle-locking devices.

Key Features

- Design: Lightweight, quarter-turn valve.

- Operation: Available in manual, gear, or actuator-operated configurations.

- Applications: Water, oil, gas, chemical processing, and more.

- Durability: High-quality materials for long-lasting performance.

- Sealing: Excellent sealing capabilities for leak prevention.

- Standards: API 609, ISO 5752, EN 593 compliance.

- Anti-Corrosion Coating: Available with anti-corrosion coatings for enhanced durability in harsh environments.

- High Flow Capacity: Engineered to provide high flow capacity with minimal pressure drop.

- Maintenance: Designed for easy maintenance with replaceable parts.

- Leak-Proof Design: Ensures leak-proof operation under high pressure.

- Special Applications: Steam, thermal, fire, chlorine, all-welded, low temperature, rapid-cycle service.

Technical Specifications

- Sizes: From 1.5″ to 24″ (DN 40 to DN 600)

- Materials: Cast iron, ductile iron, stainless steel, and special alloys (available for all sizes)

- Temperature Range: -20°C to 250°C

- End Connections: Wafer, lugged, flanged

- Design Features: Centric and double eccentric designs, suitable for bidirectional flow

- Seat Materials: EPDM, NBR, PTFE, Viton

Construction Details

- Body: Heavy-duty one-piece wafer or lugged wafer body design to withstand specified pressures

- Disc: Streamlined design with high strength and polished edges for minimal wear

- Seats: Available in resilient or metal-seated designs

- Stem: Blow-out proof design for safety

- Gland: Adjustable for enhanced sealing

- Packing: High-quality packing to prevent leakage

DIMENSIONAL DATA

Model Numbers and Sizes

| Model Number | Size (in) |

|---|---|

| AR-BV-150-40 | 1.5″ |

| AR-BV-150-50 | 2″ |

| AR-BV-150-65 | 2.5″ |

| AR-BV-150-80 | 3″ |

| AR-BV-150-100 | 4″ |

| AR-BV-150-125 | 5″ |

| AR-BV-150-150 | 6″ |

| AR-BV-150-200 | 8″ |

| AR-BV-150-250 | 10″ |

| AR-BV-150-300 | 12″ |

| AR-BV-150-350 | 14″ |

| AR-BV-150-400 | 16″ |

| AR-BV-150-450 | 18″ |

| AR-BV-150-500 | 20″ |

| AR-BV-150-600 | 24″ |

APPLICATIONS

Applications of Butterfly Valves

- Water and Wastewater Treatment: Butterfly valves are used in water treatment plants for controlling the flow of water, chemicals, and sludge. They are also employed in wastewater treatment processes.

- HVAC Systems: Butterfly valves are commonly used in heating, ventilation, and air conditioning (HVAC) systems to regulate the flow of air and water in pipes and ducts.

- Chemical Processing: In chemical plants, butterfly valves are utilized to control the flow of various chemicals, acids, and corrosive substances.

- Oil and Gas Industry: Butterfly valves play a role in the oil and gas industry, regulating the flow of crude oil, natural gas, and other hydrocarbons in pipelines and processing facilities.

- Power Generation: Butterfly valves are employed in power plants to control the flow of steam, cooling water, and other fluids in various stages of power generation.

- Petrochemical Industry: Butterfly valves are used in petrochemical plants for handling and controlling the flow of petrochemical products.

- Marine Applications: Butterfly valves are found in marine systems for controlling seawater intake, ballast systems, and other fluid-handling processes on ships and offshore platforms.

- Food and Beverage Industry: Butterfly valves are used in the food and beverage industry for handling fluids in various processes, such as liquid food production and processing.

- Paper and Pulp Industry: Butterfly valves are employed in paper mills and pulp processing plants for regulating the flow of liquids in different stages of production.

- Mining and Mineral Processing: In mining operations, butterfly valves control the flow of water, chemicals, and slurries used in mineral processing.

- Fire Protection Systems: Butterfly valves are utilized in fire protection systems to control the flow of water in sprinkler systems and hydrants.

- Pharmaceutical Industry: Butterfly valves are employed in pharmaceutical manufacturing processes for precise control of fluid flow in drug production.

- Agriculture: Butterfly valves are used in agricultural irrigation systems to control the flow of water to fields and crops.

- Construction and Building Services: Butterfly valves are used in construction for various fluid control applications, such as in plumbing systems.

- Air Handling Systems: In industrial and commercial facilities, butterfly valves regulate the flow of air in ventilation and exhaust systems.

- Automotive Industry: Butterfly valves are employed in automotive manufacturing processes for controlling fluids in different stages of production.

- Textile Industry: Butterfly valves are used in the textile industry for fluid control in dyeing and finishing processes.

- Chemical Distribution: Butterfly valves play a role in chemical distribution systems for transferring chemicals between storage tanks and processing units.

ADVANTAGES

Advantages of Butterfly Valves

- Quick Operation: Butterfly valves operate on a quarter-turn principle, allowing for rapid opening and closing with a 90-degree rotation. This makes them ideal for applications requiring quick response times.

- Compact Design: Butterfly valves have a compact and lightweight design, making them well-suited for installations with limited space or weight restrictions.

- Low Pressure Drop: Butterfly valves typically have a lower pressure drop compared to some other valve types, allowing for efficient fluid flow with minimal resistance.

- Cost-Effective: Due to their simpler design and ease of manufacturing, butterfly valves are often more cost-effective than other valve types, making them an economical choice for various applications.

- Versatility in Sizes: Butterfly valves are available in a wide range of sizes, from small to very large, making them versatile for different applications and industries.

- Ease of Installation: The straightforward design of butterfly valves simplifies the installation process, contributing to overall cost and time savings.

- Ease of Maintenance: Butterfly valves typically have fewer moving parts compared to some other valves, resulting in lower maintenance requirements. This can lead to reduced downtime and cost savings over the valve’s lifecycle.

- Application Versatility: Butterfly valves find applications in various industries, including water and wastewater treatment, HVAC systems, chemical processing, oil and gas, and more, showcasing their versatility.

- Bi-Directional Flow: Butterfly valves are designed to handle bidirectional flow, allowing flexibility in system design and operation.

- Reduced Water Hammer: The quick opening and closing action of butterfly valves can help reduce the risk of water hammer in certain applications.

- Good for Large Diameter Pipelines: Butterfly valves are well-suited for large-diameter pipelines, where their compact design and efficient flow control make them advantageous.

- Corrosion Resistance: Depending on the materials used in construction, butterfly valves can be corrosion-resistant, making them suitable for handling corrosive fluids.

- Wide Range of Materials: Butterfly valves can be constructed from a variety of materials, including metal, plastic, or a combination, allowing for compatibility with different types of fluids.

- Energy Efficiency: The low-pressure drop and efficient flow characteristics of butterfly valves contribute to energy efficiency in fluid systems.