• ARO-OPA-IOA

What is an Integral Orifice Plate Assembly?

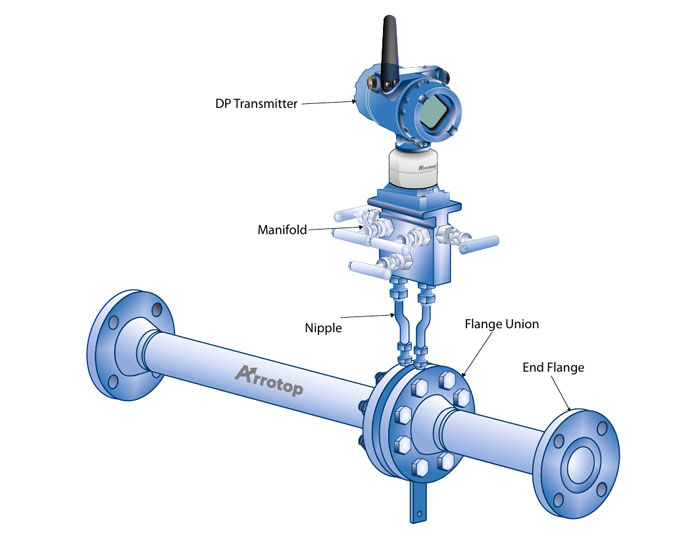

Flow measurement in pipelines is critical for various industrial processes. Arrotop’s Integral Orifice Assembly offers a precise and efficient solution for measuring fluid flow. By integrating the orifice plate with the measuring instrument, this assembly simplifies installation, improves accuracy, and reduces maintenance costs.

Product Data

The Arrotop Integral Orifice Assembly (ARO-OPA-IOA) is designed to provide accurate and reliable flow measurement for liquids, gases, and steam. This fully integrated flow meter eliminates the need for additional fittings, tubing, valves, adapters, and mounting brackets, thereby reducing welding and installation time. By directly mounting Differential Pressure Transmitters on the orifice assembly, installation costs and potential leak points are significantly reduced.

Direct Mounting Capability

The ARO-OPA-IOA Integral Orifice Assembly’s direct mounting capability allows for the easy attachment of Differential Pressure Transmitters via a Three/Five-Valve H-type manifold. This configuration streamlines the installation process and enhances measurement accuracy by eliminating potential sources of error associated with long impulse lines.

Technical Information

| Model Number | ARO-OPA-IOA |

|---|---|

| Material | Orifice Plate, Body, Pipe, SS 304/L, 316/L, Duplex, Super Duplex, Hastelloy, Duplex, Monel, Inconel, Titanium (special alloys on request) |

| Process Temperature Limits | -40 to 230°C for direct / remote mount |

| Line Size | 1/2″, 1″, 1.1/2″ |

| Process Connection | Flanged, NPT |

| Fluid Types | Liquid, Gas, Steam |

| Pressure Tapping | Corner tappings recommended for sizes upto 1.1/2, flange taps from 2″ onwards |

| Accuracy | ± 0.5% of volumetric flow rate |

| Routine Tests | PMI Test, Dye Penetration Test, Hydro Test, Radiography Test, Calibration, NACE |

| Mounting | Direct mounting through three / Five-Valve H-type manifold |

| Meter Run Pipe Length | Upstream length of 750 mm and downstream length of 250 mm |

| Differential Pressure Measurement | Integrated design reduces ID uncertainly and plate misalignment issues |

Applications of Arrotop Integral Orifice Plate Assembly

The Arrotop Integral Orifice Plate Assembly is a precise flow measurement device used in various industries for measuring the flow rate of liquids, gases, and steam. Its applications span across several sectors due to its accuracy, reliability, and ease of installation. Here are some common applications:

- Oil and Gas Industry: Used in exploration and production operations to measure the flow of crude oil and natural gas. Applied in pipelines to monitor and control the transportation of oil and gas. Utilized in refineries and petrochemical plants for process control and product measurement.

- Chemical and Petrochemical Industry: Used to measure and control the flow of various chemicals and feedstocks in manufacturing processes. Essential for maintaining the correct chemical reactions and ensuring product quality.

- Power Generation: Applied in both conventional and nuclear power plants to measure the flow of steam, feedwater, and cooling water. Critical for maintaining efficient and safe operations.

- Water and Wastewater Management: Used in water treatment plants to measure the flow of raw and treated water. Essential for monitoring and controlling the treatment processes to ensure water quality.

- Food and Beverage Industry: Utilized to measure the flow of ingredients and products in manufacturing processes. Ensures consistent quality and helps in maintaining regulatory compliance.

- Pharmaceutical Industry: Applied in the manufacturing of pharmaceuticals to measure the flow of various liquids and gases. Essential for maintaining precise control over production processes to ensure product quality and compliance with regulations.

- HVAC Systems: Used in heating, ventilation, and air conditioning systems to measure the flow of air and other gases. Ensures efficient operation and helps in maintaining desired environmental conditions.

- Pulp and Paper Industry: Applied in the production processes to measure the flow of pulps, chemicals, and water. Essential for process control and ensuring product quality.

- Metallurgical Industry: Used in the production of metals to measure the flow of gases and liquids involved in various processes. Helps in maintaining process efficiency and product quality.

- General Industrial Applications: Utilized in various other industrial processes where accurate flow measurement is critical for process control and optimization.

Advantages of Arrotop’s Integral Orifice Plate Assembly

The Arrotop Integral Orifice Plate Assembly offers several advantages that make it a preferred choice in industrial flow measurement applications:

- Accuracy: Provides precise measurement of flow rates across a wide range of operating conditions, ensuring reliable data for process control and optimization.

- Versatility: Suitable for measuring the flow of liquids, gases, and steam in various industrial processes, making it versatile for different applications.

- Durability: Constructed from robust materials such as stainless steel or other corrosion-resistant alloys, ensuring long-term reliability even in harsh operating environments.

- Ease of Installation: Designed for easy installation and maintenance, minimizing downtime and reducing installation costs.

- Cost-Effectiveness: Offers a cost-effective solution for flow measurement compared to other complex flow measurement devices, with low initial investment and operational costs.

- Minimal Pressure Loss: Designed to minimize pressure loss across the orifice plate, optimizing system efficiency and reducing energy consumption.

- Compatibility: Compatible with a wide range of process conditions and fluid types, making it suitable for diverse industrial applications.

- Regulatory Compliance: Meets international standards and regulatory requirements for accuracy and performance, ensuring compliance with industry standards.

- Integrated Design: The integral design simplifies the assembly and reduces potential leak points, enhancing overall reliability and safety.

- Proven Performance: Backed by extensive field testing and operational experience, demonstrating reliable performance in various industrial environments.

Liquid & Gas Applications

- Open high and low side valves.

- Open the equalizer valve.

- Pressurize the line

- Ensure no gas remains by bleeding

drain/vent valves - Check transmitter zero

- Close the drain/vent valves.

- Close the equalizer valve.

- Close the low side valve

- Open the low side valve to start the

system.

Steam Applications

- Remove pressure from the line.

- Open high, low, and equalizer valves.

- Fill manifold and transmitter with water

using drain vents. - Pressurize the line.Tap components to

remove trapped air - Check transmitter zero

- Close the equalizer valve.

- Close the low side valve

- Open the low side valve to start the

system.